Challenges in Rubber Industry

By Dr. Samir Majumdar

Flat : H-701, Neel Padm Kunj, Vaishali,

Opp. Dabur Chawk, Ghaziabad. India.

Introduction

Today’s hot topic is energy, particularly in

the scenario when crude price is increasing almost everyday. Energy is

definitely an essential element of today’s society. We can not even dream

without energy. People simply expect it – and demand it and therefore, people

of today virtually takes it for granted that it is there, you pay for and have

it. Number of times every day – at the touch of a switch, turn of a key or push

of a small button – energy is delivered instantly.

Today’s energy is used in cultivation, creating products,

product movement, generating commerce in safer, stronger, and more efficient

than at any time in the history. With on going liberalization process there has

been a drastic change in the Indian economy and there is a sign of positive

growth of both Agricultural and Industrial production. Automobile industry

growth in any country is driven from growth on the transportation. India’s

transportation growth is basically driven from agricultural growth.

Historic trend of agricultural growth in India

is 7 – 8% whereas, for Automobile industry, it is 5 – 6% and the exceptional

year was 2003 and 2004 where the Automobile industry has shown growth close to

14%

In the year 2004, the average growth of vital

truck segment has been recorded to above 12%. Average passenger car growth has

been close to 10%. Scooter growth rate has been 9% and motorcycle growth rate

by 7%. OTR growth rate has been close to 5% per annum. The above growth rate

figure is of OEM.

Some of the major OEM manufacturers in India

are Maruti, Toyota, Ford, Hyundai, General Motor, Honda City, Fiat, Telco,

Mercedes, Mitsubishi, Mahendra & Mahendra, Swaraj Mazda, Volvo, TVS, Bajaj Auto,

Hero Honda, Suzuki Motor etc.

Some of these foreign companies have taught us

good practices in quality processes lke 5S, TPM, TQM etc. for industry

discipline, managing product processing, defects, managing inventory and

dispatching to customer for highest level of customer satisfactions, customer

relations and so on.

Future Growth of Indian Automobile

Rubber industry growth in all countries is

linked with growth of Automobile industry. Future growth of Indian Automobile

Industry is evident because of following :

-

Economical growth of 7-8%

(7.6% in 2004 – 2005)

-

India is the fifth largest

economy in the world

-

India has 3rd

largest GDP in the entire continent of Asia

-

A huge population of above

1.1 billion

-

Average income of lower middle

class and middle class people are increasing due to economical growth on the

investment policy by Government of India.

-

Constraints of Indian Railways

to meet the growing demand for passenger and goods transport.

-

Road transport is the major

link for essential goods to the rural masses and transportation of farm

produce to the cities.

-

Development of golden

quadrilateral and North-South & East-West Corridors National Highways.

-

More and more capacity

utilization in Automobile industries.

-

Easy financing for new and old

vehicle purchase.

India as a Leading Country in the World

Time has changed and is changing very fast.

Developed nations are looking at India with more respect now. Indian

contribution in the ancient ages had been known but unfortunately these were not

been well communicated to the rest of the world and many of these information

were lost under the shadow of British rule in India over a period of 200 years.

Many important information are coming now, were not known to the world.

Presently India is world’s largest democracy

and world’s 4th largest economy. 15 of the world’s major Automobile

makers are obtaining components from Indian companies. This business fetched

India $1.5 billion in 2003, and will reach $15 billion by 2007. World-renowned

TQM expert Yasutoshi Washio predicts that Indian manufacturing quality will over

take that of Japan in 2013. Some more highlights in a nutshell are :

-

India is more than 5000 year

old ancient civilization.

-

India first invented the

Number System. Zero was invented by Aryabhatta. The place value system, the

decimal system was developed in India in 100 BC.

-

Aryabhatta was the first to

explain spherical shape, size, diameter, rotation and correct speed of Earth

in 499 AD.

-

The World’s first university

was established in India in Takshila in 700 BC. Students from all over the

World studies more than 60 subjects.

-

The University of Nalanda

built in the 4th century was one of the greatest achievements of

ancient India in the field of education.

-

Sanskrit is considered the

mother of all higher languages. Sanskrit language is known to be the most

precise, and therefore suitable language for computer software-a report in

Forbes magazine, July 1987.

-

There are 325 languages spoken

in India, have 1652 dialects and having 18 official languages, which is very

unique anywhere in the World within 29 states, and 5 union territories.

-

Having population close to

1.3bn within an area of 7516 KM – coastline.

-

There are 5600 dailies, 15000

weeklies and 20000 periodicals in 21 languages with combined circulation of

142 million.

-

Current GDP rate close to 8%,

$576bn.

-

India is the largest English

speaking Nation in the world and 2nd largest pool of Engineers and

Scientist in the World.

-

McKinsey believes India’s

revenue from the IT industry will reach $87 bn by 2008.

-

Flextronics, the $14 bn global

major in Electronic manufacturing services, has announced that it will make

India a global competence centre for telecom software development.

-

Tata Motors paid $118 mn to

buy Daewod commercial vehicle company of Korea.

-

Ranbaxy, the largest Indian

pharmaceutical company, gets 70% of its $1 bn revenue from overseas operations

and 40% from USA.

-

India is one of the world’s

largest diamond cutting and polishing centres, its exports were worth $6bn in

1999. About 9 out of 10 diamond stones sold anywhere in the world, pass

through India.

-

Mobile phones are growing by

about 1.5 mn a month. Long distance rates are down by two-thirds in five

years and by 80% for data transmission.

-

Wal-Mart sources $1 bn worth

of goods from India – half its apparel. Wal-Mart expects this to increase to

$10 bn in the next couple of years.

-

India’s INSAT is among the

world’s largest domestic satellite communication systems.

-

India’s Geo-synchronous

Satellite Launch Vehicle (GSLV) was indigenously manufactured with most of the

components like motor cases, inter-stages, heat shield, cryogenic engine,

electronic modules all manufactured by public and private Indian industry.

-

India is providing aid to 11

countries, writing-off their debt and loaning the IMF $300M. It has also

prepaid $3bn owed to the World Bank and Asian Development Bank.

-

The Indian pharmaceutical

industry at $6.5bn and growing at 8-10% annually, is the 4th

largest pharmaceutical industry in the world, and is expected to be worth $12

bn by 2008.

-

Its exports are over $2 bn.

India is among the top five bulk drug makers and at home, the local industry

has edged out the Multi_national companies whose share of 75% in the market is

down to 35%. Trade of medicinal plants has crossed $900M already.

-

There are 170 biotechnology

companies in India, involved in the development and manufacture of genomic

drugs, whose business is growing exponentially.

-

With more than 250

universities, 1,500 research institutions and 10,428 higher-education

institutes, India produces 200,000 engineering graduates and another 300,000

technically trained graduates every year. Besides, another 2 million other

graduates quality out in India annually.

-

The Indian Institute of

Technology (IIT) is among the top three universities from which McKinsey &

Company, the world’s biggest consulting firm, hires most.

Rubber Products

India can produce now all types of rubber

products beginning from critical applications in information technology,

footwear, cables, pharmacy, critical products of passenger car profiles, hose,

conveyor belt, transmission belts, V-belts, gasket, oil seals to higher rated

passenger car tyre and all steel truck tyres for domestic use as well as for

exporting to abroad.

As on today, India is making more than 35000

different kinds of rubber products in 6000 different units all over India for

domestic as well as for export whose turn over is close to US$ 5 bn per annum.

Out of these 6000 units, roughly estimates are :

-

30 number of large scale units

-

300 number of medium scale

units and

-

5600 number of small scale

units

Today large and medium sectors are not so much

in threat as much as small sectors. Large and medium sectors have money power

and they have options for diversification, which may not be true for small

sectors and their current situation, is either survive or die. Today’s major

challenge for small sectors are on cost, quality and productivity.

Challenges

Our present challenges are with the small-scale

units and the major challenges are how they can cope up in the current scenario

of :

-

Global Competition

-

Rising Fuel Cost

-

Rising Raw Material Cost

-

Reduction in Import Duty

Our Potentials

Our scope and potentials are plenty. When

Japan’s rubber kg per person is close to 14, India is having only less than 1 kg

(Fig. 1) Other advantages of India in rubber fields are :

-

Large producer of NR (Consumed

approximately 1.0m MT of rubber in 2005)

-

India is 4th

largest consumer of Rubber

-

Large domestic market

-

Rapid growth of automobile

sector

-

Academic based technologists

-

On going economical reforms

Rubber Consumption Pattern

Fig. 1. Rubber Consumption Pattern.

1-India, 2-China, 3-Europe, 4-North America, 5-Japan.

New Concept

What we really need now is better understanding

in the business. It is not enough that we know making a product and the

existing profit margin in the domestic market is also known. Our strategy needs

to be changed entirely from domestic market focus to international market

focus.

India’s small scale industry is driven by

business community. In most cases the owner becomes the technical man,

marketing man, quality man, production man, commercial man etc. – which means

the owner is everything. In most cases owner’s relatives will be holding all

key position in the organization and as a result multifunctional communication

is lost and finally loses the opportunity for the future growth of the company.

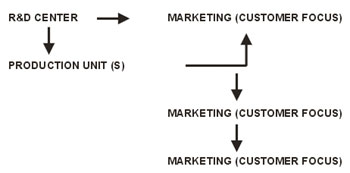

We need to bring the concept of R&D center very

fast in small manufacturing sectors. R&D center does not mean purchasing of

costly equipments and publishing of theoretical papers in different journals.

R&D center in small organization should work in harmony with production,

marketing and customer.

At least all manufacturing organization,

however small it is, will have a quality control department for controlling

incoming raw material, process and identifying the quality of product suitable

for customers. R&D center can be made as a special wing from existing Quality

Control department only.

R&D center performs the company objectives

today, tomorrow and after 5-10 years from now. Which means R&D center

practically provides business directives for present and future. This is very

true in all developed nations. We need to bring on these concepts as fast as

possible.

R&D Center (Provides Business Directives)

Indian R&D centers should take the advantages

of academic based technologists and train them as per company requirements. For

rubber industry alone India has 10 Degree Colleges, 2, Diploma Courses, 3 Post

Doctorate Research Institutes, 4 Research Institutes, 14 Testing Laboratories

and 6 Certifying Institutes. Selection of right candidate and training of them

are important in any organization and the next important part is to provide

atmosphere to retain those R&D executives.

A right R&D executive should have following :

-

Capability

-

Conceptual understanding

-

Confidence

-

Attitude

-

Dedication

-

Information exploration

attitude (Domestic/International)

-

Multilevel contacts

-

Educating internal customers

-

Continuous Resource

development

Most important part is an approach should be

made to monitor continuous resource finding in R&D center. They should be given

appropriate training and these executives, intern, can train others. Per need

of the company, an aim should be there for restructuring the R&D wing as and

when required.

As already emphasized, R&D concept can begin

from the existing quality control wing itself. For developmental jobs if

required out side testing may be considered, if the cost of the equipments are

not affordable. A time may come when out side testing will gradually become

expensive, only at that time it might be worth while to procure the equipment

for future cost reduction.

All Indian R&D Center has to be interactive

with Production and Marketing to give Business Directives (Fig.2). The most

important part, which is also lagging in our existing R&D center that any R&D

center has to be based on customer focus to integrate on raw material

requirement, processing requirement and quality of product suitable for

customers and finally gives business directives in the scenario of political

changes and economical changes.

Fig.2 : R&D Center to be interactive with

Production and Making to give Business Directives.

Quality

All manufacturing industry will have a quality

wing for controlling in coming material, controlling process and the finished

goods. Quality of product is – Attributes Accepted by Customers.

Attributes could be anything, look, design,

performance, durability, comparison etc.

-

Design, Look

-

Performance

-

Durability

For acceptable level of quality, you need

appropriate technology. You may not compete any more with the old technology

you have. Modernisation of the manufacturing unit is a must and R&D can play

major role in that. Cost of quality are of two categories:

-

Cost of Lack of Quality

-

Cost of Achieving Quality

Cost of lack of quality can again be due to two

primary reasons; internal failure cost and external failure cost. External

failure costs are damaging since most cases this will be returned material from

the customers due to customer dissatisfaction and therefore it adds

transportation cost as well as the cost of losing the customers.

Fig.3 : R&D can Concentrate on Continuous Improvement of Product

When quality of the product is being

maintained, there are two types of costs; prevention cost and cost for

improvement and in the later part R&D can play the major role.

There has to be some technology background

through which the current product is being made. For improved quality in the

competitive scenario, better technology might be required and R&D can help in

Product Design and Development, Process Design and Development, Compounding

Design and Development, Finding alternatives, Development of man power etc.

R&D will be basically for all necessary

alternatives in the competitive market and it is to be focused on cost saving on

all activities in manufacturing the products. Practically R&D wing helps in

cost saving in developing the right product and right man power such that the

continuity of the right product is maintained. Concept of right product,

changes with time because the demand pattern in the society is changing

continuously.

Fig. 4 : Practically R&D

wing helps in cost saving in developing the right product and right man power.

-

Product Design and Development

-

Process Design and Development

-

Compounding Design and

Development

-

Finding alternatives

-

Development of man power

Reference

-

Manufacturing Profiles for

Automobiles. Dr. S. Majumdar, Rubber Chem Review (17-23) March-April 2005.

-

Carbon Black, Dr. Samir

Majumdar, Marketing In a New Era : A Global Perspective, Proceeding of Amity

Business School, Noida, at Banquet Hall, Hotel Ashoka, Chankyapuri, New Delhi,

Dec. 21, 2004.

-

Challenges, Prospects and

Vision of the Indian Rubber Products Manufacturing Industry, Shir Raghupati

Singhania, VC & MD – JK Industries Ltd., International Rubber Journal (24-28),

June 2005.

-

CBFS, Dr. Samir Majumdar,

Rubber Chem Review, July – August (17-23) 2005.